This is my logo—a sine wave made out of my initials (JS). I've found that sine waves are in everything I do, from physics, to ECE, to music. You may notice this same logo on my necklace elsewhere on this page. I designed it in Fusion 360 and 3D printed it to make the necklace.

Hi, I'm Jonah.

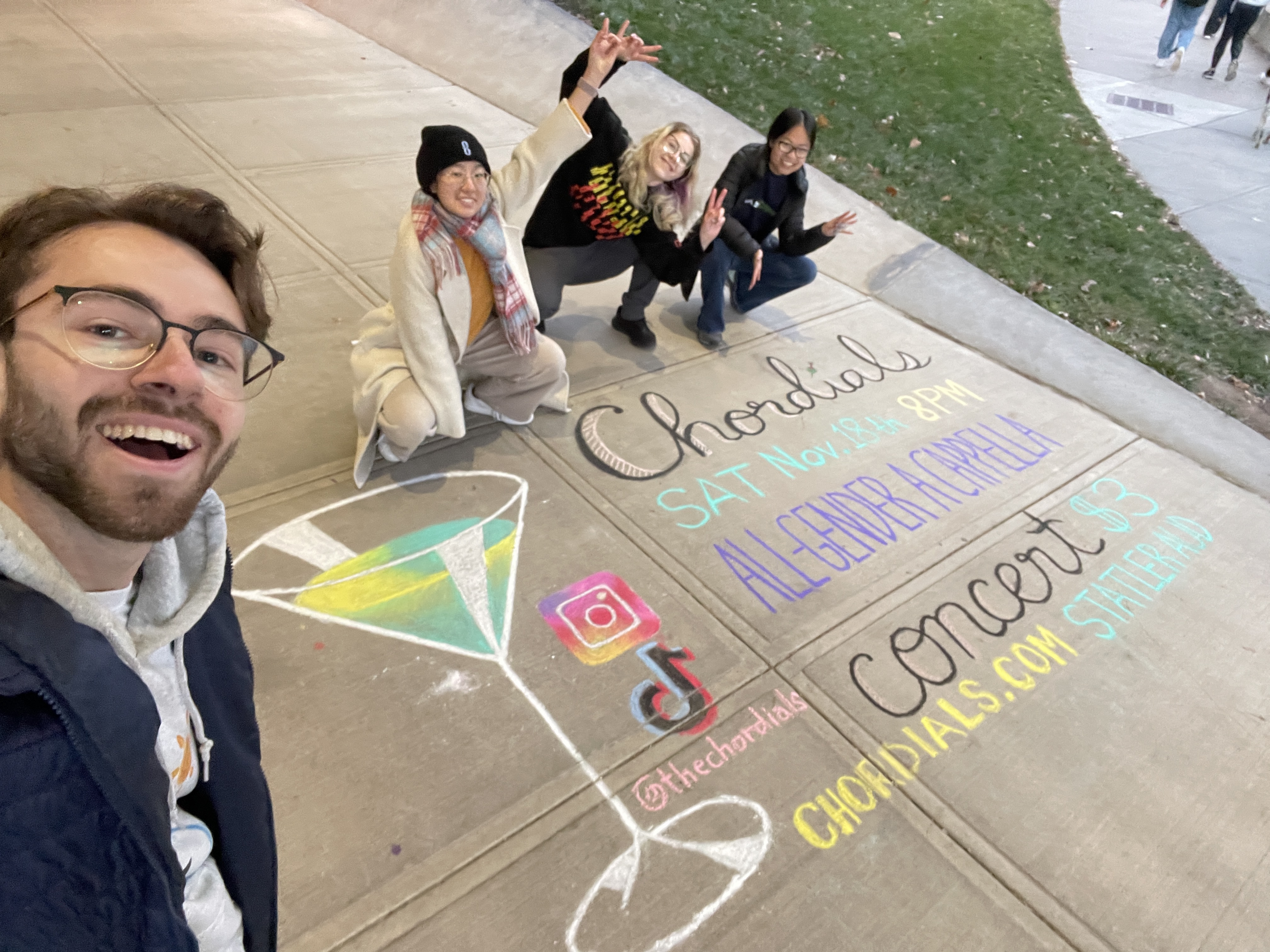

Welcome! I'm a master's student at Cornell University studying Electrical & Computer Engineering. My interests include optics, photonics, solid state physics, and quantum computing. In my free time, I enjoy singing with my a cappella group, The Chordials, and writing my own music.

| Summers 2023, 2024

| Summers 2023, 2024

| Sept. 2023 - May 2024

| Sept. 2023 - May 2024

The Chordials A Cappella | Dec. 2022 - Dec. 2024

The Chordials A Cappella | Dec. 2022 - Dec. 2024